Eichler Radiant Heat: Fix It, Replace It, or Go Hybrid?

- Craig Smollen

- Aug 28, 2025

- 5 min read

Updated: Aug 29, 2025

Classic Eichlers heat the house with warm water circulating through pipes buried in the slab. When those loops are intact, you get the holy trinity of comfort: quiet, even, and dry‑air friendly. When a loop leaks, water can vanish into the earth and an auto‑fill valve might hide the problem—until corrosion and cold toes file a complaint.

Step 1 — What’s in your slab: copper or steel?

Mid‑century supply quirks meant some early ’50s Eichlers got steel radiant tubing during a copper shortage; later homes typically went back to copper. That matters: many copper systems are repairable; failing steel systems are often on borrowed time. Quick field tell, find the manifold and bring a magnet: if it sticks, it’s steel. Symptoms of leaks include higher water bills, warm spots, hairline cracks, the sound of water when everything’s off, and that tell‑tale white efflorescence along the foundation.

Your 3 paths: Fix it, Replace it, or Go Hybrid

A) Fix it (when it’s worth saving)

If testing shows your copper loops are fundamentally sound, targeted pinhole repairs can be a smart play—often in the $1,850–$2,500 per leak range, depending on access and finishes. Key rule: don’t keep “refreshing” the system with new water; oxygen in fresh water speeds corrosion. Find the leak, fix it, keep the loop tight.

Pull‑quote: “Repair what’s good, replace what’s not. And never anger a happy slab.” — every seasoned Eichler tech, more or less

B) Replace it (when the slab piping is shot or steel)

You’ve got two Marin‑tested ways to keep floor‑based radiant without turning the house into a duct farm.

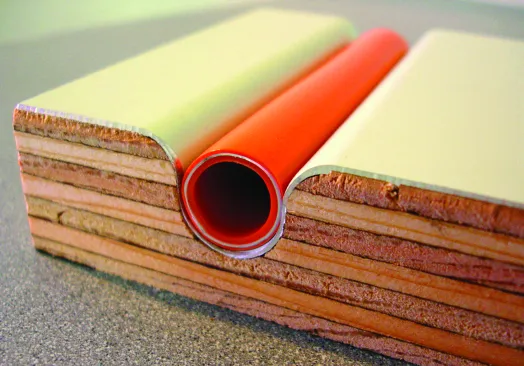

Route 1: Cut slots and install new PEXFor steel systems or copper that’s given up, we’ve carved shallow grooves in the slab and laid modern 1/2” inch PEX, then resurfaced and finished. Loud? Yes. Dusty? You bet. Effective? Absolutely and it preserves the Eichler feel. (Bonus: it’s a great time to pick radiant‑friendly flooring.)

Route 2: Overlay with Warmboard®When you’re remodeling or you want fast, even response, Warmboard‑R panels (13/16" thick, 2'×4") install as an overlay over your slab, while Warmboard‑S (1‑1/8", 4'×8", structural) shines in additions or full gut jobs. Both accept ½" PEX at 12" on‑center and use a thick aluminum skin to spread heat quickly and evenly. Translation: fewer “zebra stripes,” happier toes, and simpler controls. We’ll design clean transitions at doors and thresholds.

Shop talk: We spec Warmboard around Marin for its responsiveness and predictable results; the manufacturer’s own docs confirm the dimensions, routing, and aluminum skin that make it work.

“What about epoxy lining the old pipes?”

Short answer: we rarely recommend it for in‑slab hydronic loops. Commercial epoxy lining products often have temperature‑warranty ceilings around 140°F, and while radiant can run cooler, boiler systems and operational spikes can exceed that, erasing any safety margin. Epoxy lining is more common in potable or drain pipes than aging thin‑wall radiant loops. We prefer new, warrantied PEX or Warmboard so you’re not gambling under your floors. (If you’re considering epoxy, get the exact temp and warranty limits in writing.)

Boilers & brains (controls), briefly

Modern condensing boilers are typically 90–96% AFUE, but they only achieve that when return water temps are low enough for the flue gases to condense—exactly what a well‑designed radiant system delivers. We’ll design the system so your boiler actually condenses, not just claims to. (Non‑condensing models typically sit lower on the efficiency ladder.)

Marin‑specific notes from the field

Flooring matters. Tile, stone, and many engineered hardwoods are terrific with radiant. Thick carpet/pad can cut output dramatically, don’t smother your slab.

Sliding door clearances are tight on Eichlers. If you’re adding panel systems over the slab, we’ll coordinate thresholds and heads so you’re not stepping up into your yard.

Leak clues love to hide. Warm spots, water‑meter creep, and that powdery exterior line at the slab edge all tell a story. We bring the right tools (and a magnet) to translate.

Photo from our files

(We’ll drop your image right here in the live page.)

Caption: Slot‑cut retrofit in an Eichler slab, new ½" PEX laid into shallow grooves prior to resurfacing.

Alt text: Grooved concrete slab with new PEX tubing installed for radiant heat retrofit.

Homeowner FAQ

How much height will Warmboard add to my floors?Warmboard‑R is 13/16" before finished flooring; Warmboard‑S is 1‑1/8". We draw door transitions and slider thresholds so it looks intentional and feels seamless.

Can I keep my hardwood?In many cases, yes, especially with engineered products rated for radiant. We’ll vet species, thickness, and installation method. (Avoid thick carpet/pad over radiant.)

How long will my house be torn up?Slot‑cutting is the noisiest, dustiest phase; we stage the mess, isolate work zones, and coordinate with your flooring schedule. Warmboard overlays are often faster and cleaner because we’re not carving the slab. (Your exact timeline depends on scope, kitchens, baths, and finish upgrades add time.)

Is repair cheaper than replacement?If you’ve got copper and a short leak history, pinhole repairs can be cost‑effective ($1,850–$2,500 per leak). With steel or chronic leaks, replacement or Warmboard overlay usually wins on lifetime cost and sanity.

Will a new boiler save me money?A properly designed condensing boiler matched to radiant’s low temps can run 90–96% AFUE; controls and return temps matter. We right‑size the unit and protect your investment.

Closing Summary:

Eichler radiant is one of the best ideas ever poured into concrete. When it’s healthy, it’s the quiet workhorse under your feet, no drafts, no drama, just steady comfort. The trick is knowing whether you’ve got copper worth saving or steel on borrowed time, and then choosing the right fix with a carpenter’s common sense instead of a gambler’s hope.

If testing says your copper is mostly happy, targeted repairs keep the good stuff rolling, think $1,850–$2,500 per leak depending on access and finishes, and for the love of warm toes, keep fresh oxygenated water out of the loop. If you’re staring down steel or a history of leaks, don’t duct your way out of a floor that was born to be warm. Slot‑cut PEX puts new life in the slab you already own; Warmboard® overlays add fast, even heat with clean transitions and modern controls. Both preserve that Eichler feel; neither turns your home into a Rube Goldberg furnace.

Skip the epoxy roulette. It’s a fine product in the right pipes, but in thin, in‑slab loops with heat spikes, the warranty math gets wobbly. Pair your rebuilt system with a properly designed condensing boiler so it actually condenses (and saves), and choose finishes that play nice with radiant, tile, stone, and many engineered woods.

Bottom line: fix what’s fixable, replace what’s not, and don’t anger a happy slab.

Comments